Restoring a Supreme Model 666 Combination AF and RF Metered Signal Generator

The model 666 signal generator is a 1948 update of the model 561 AF/RF generator first introduced in 1939. It has the same functionality as the 561 with a couple of tube updates and a new color scheme.

According to Supreme's service bulletins the model 666 was out of production by the second quarter of 1953 due to parts shortages and government restrictions. I suppose this was due to the war in Korea.

According to Supreme's service bulletins the model 666 was out of production by the second quarter of 1953 due to parts shortages and government restrictions. I suppose this was due to the war in Korea.

|

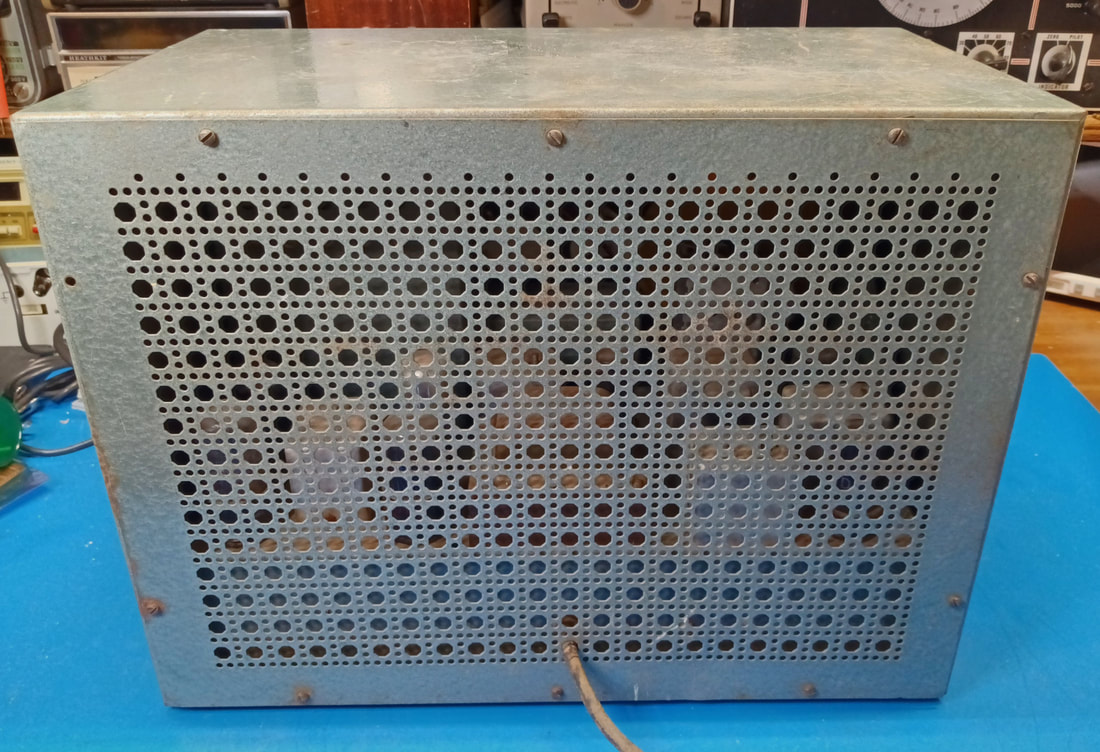

The generator is in pretty good condition considering its age. There's a little rust here and there, but nothing too terrible. Likewise, there are some scratches on the case and front, but again, nothing horrible.

I purchased this generator simply out of curiosity about what Supreme had changed when they updated the model 561 to create this new model. I assumed the paint would be a gray wrinkle finish as advertised for the 561 in their 1947 catalog, but it's actually a hammered finish with a blue-green tint. Supreme called this new finish "Blue Hammerloid" in their 1948 catalog, but it looks more green than blue to me. And the front panel is described as satin aluminum and blue with maroon trim. This generator is serial number 455, and if the front panel was originally made of aluminum then Supreme had changed to steel by the time this one was manufactured. Possibly this was another shortage due to the war. |

|

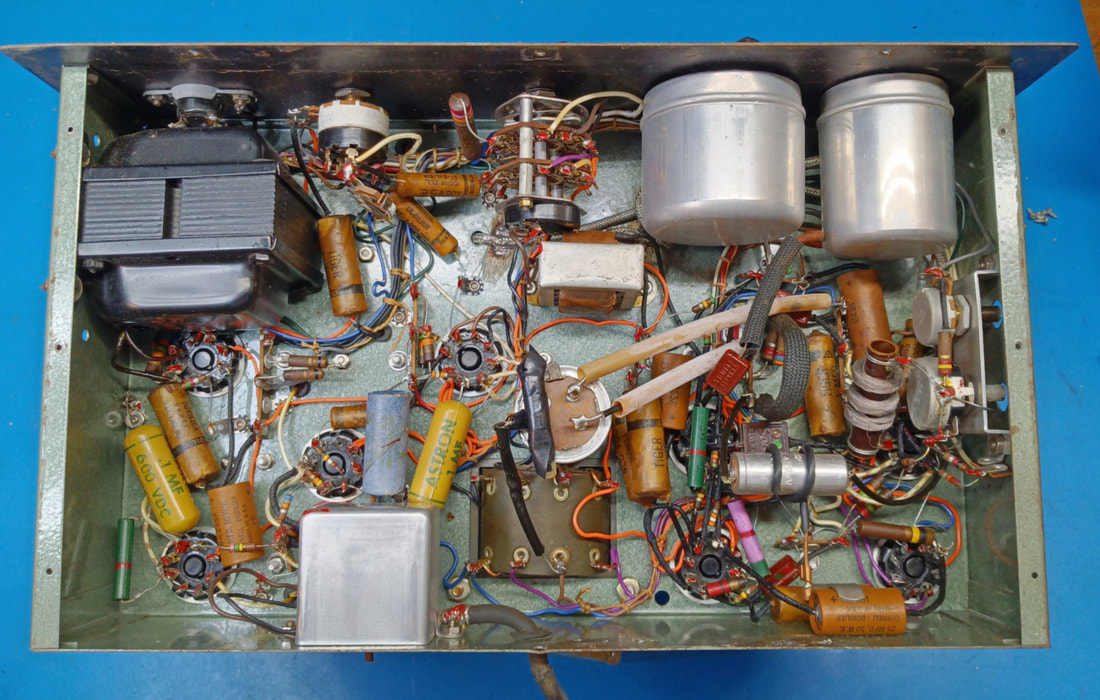

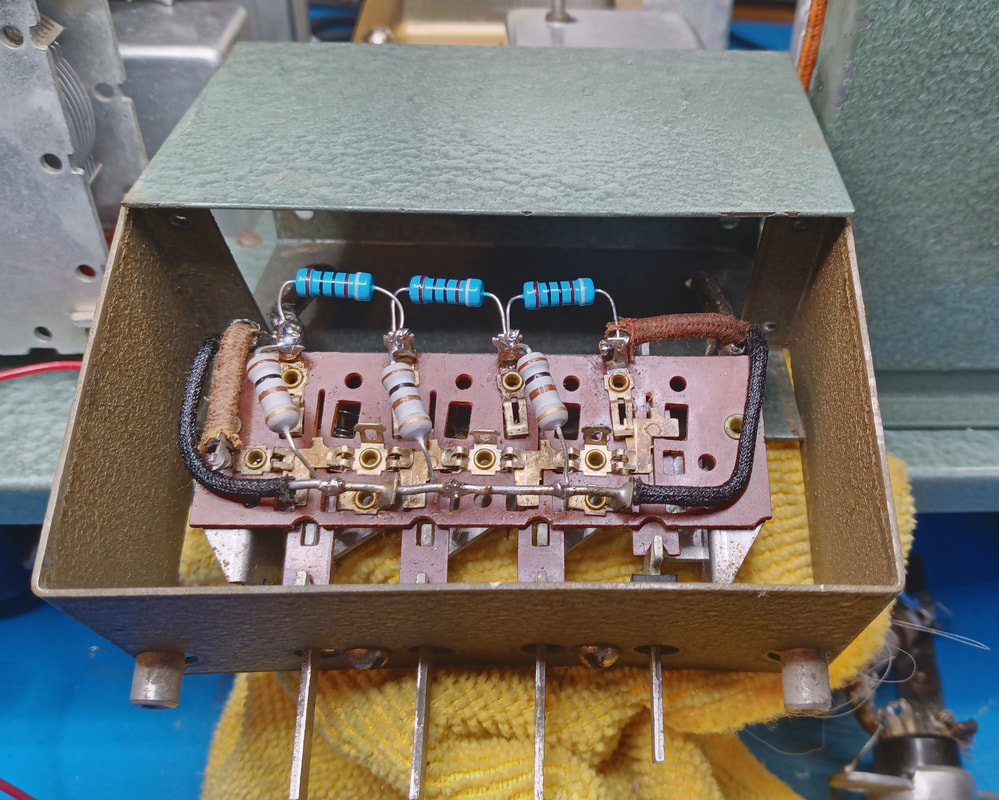

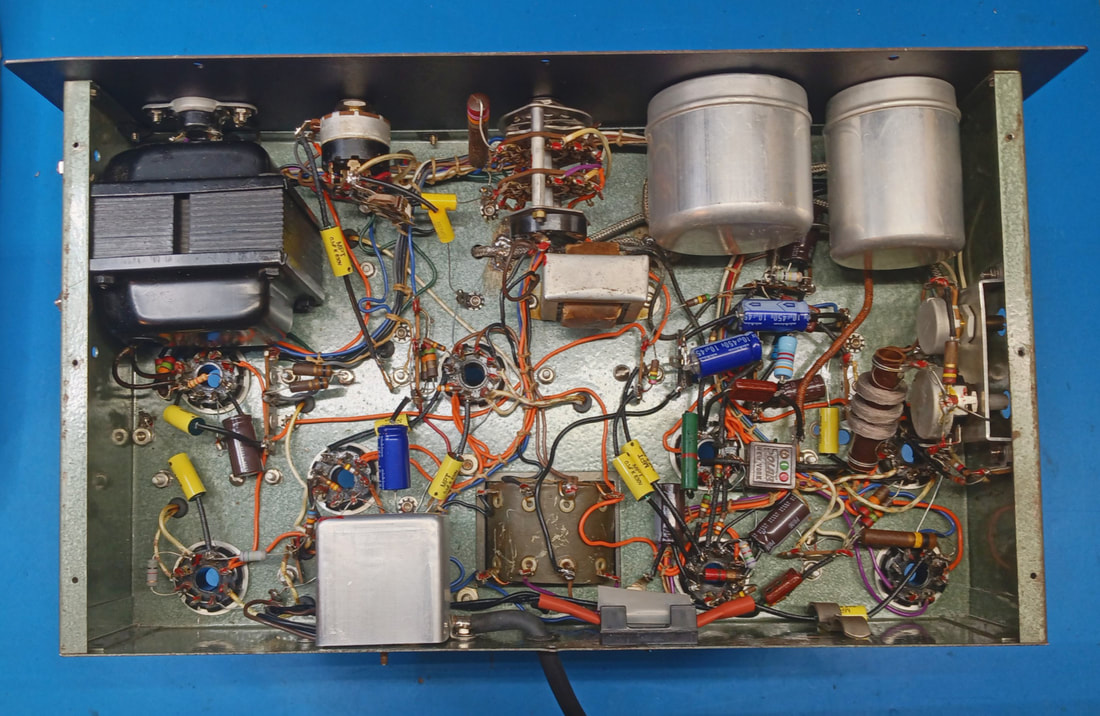

Under the chassis it looks to be mostly original. It has been worked on in the past and someone replaced all the power supply electrolytic capacitors, several waxed paper caps, and a couple of resistors.

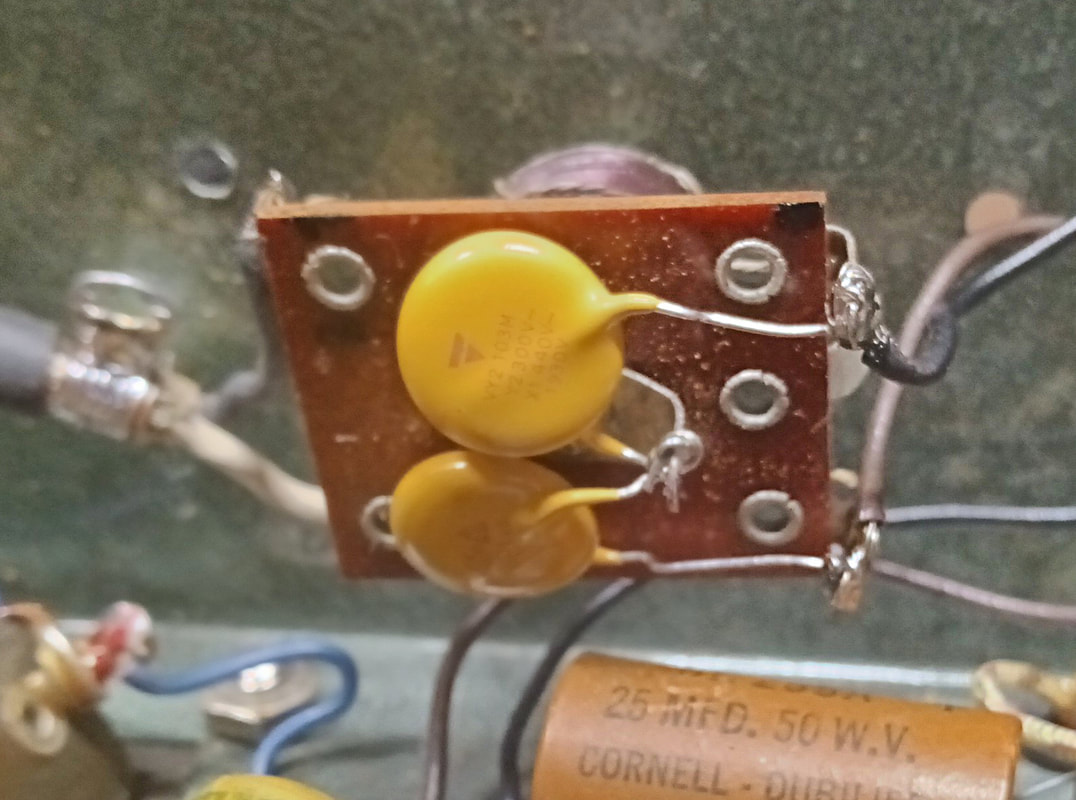

Two of the filter caps had been replaced with a multi-section can standing on end. The two yellow plastic encapsulated Astron capacitors don't look to be original either, and may be film or di-film caps. |

|

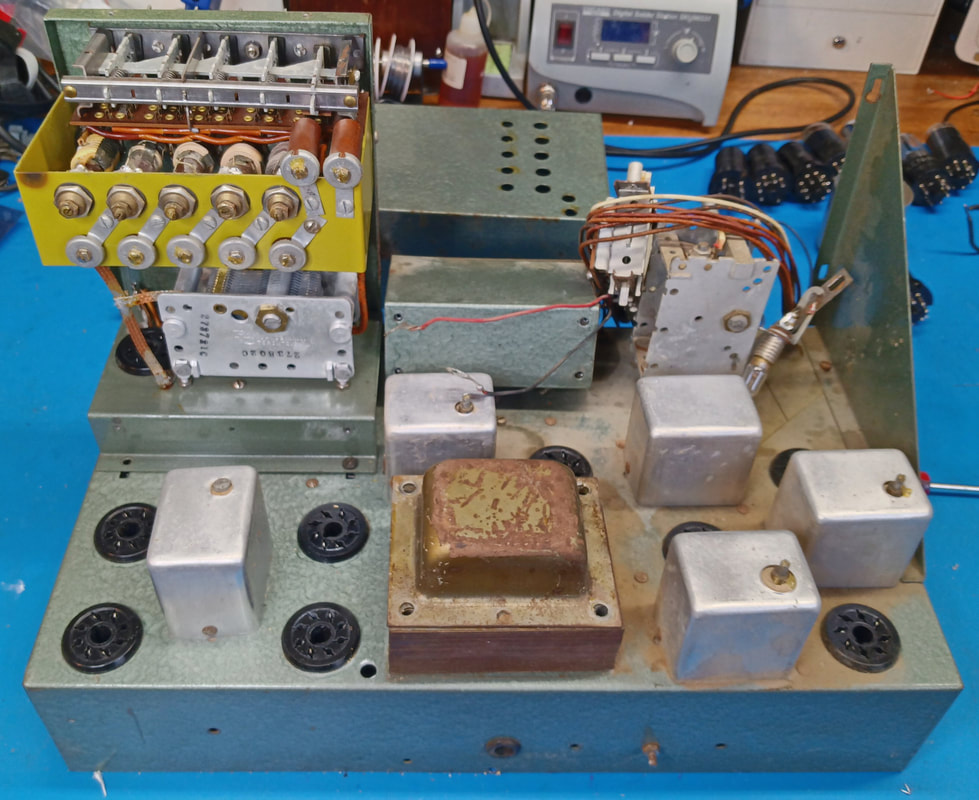

The front panel was removed to gain access to the dials and the multiplier box, and to allow for easy removal of the RF sub chassis. It also makes it much easier to clean up the top of the chassis and the dials, and the front panel itself. Plus the back has a little surface rust so I will clean it up and refresh the paint.

|

|

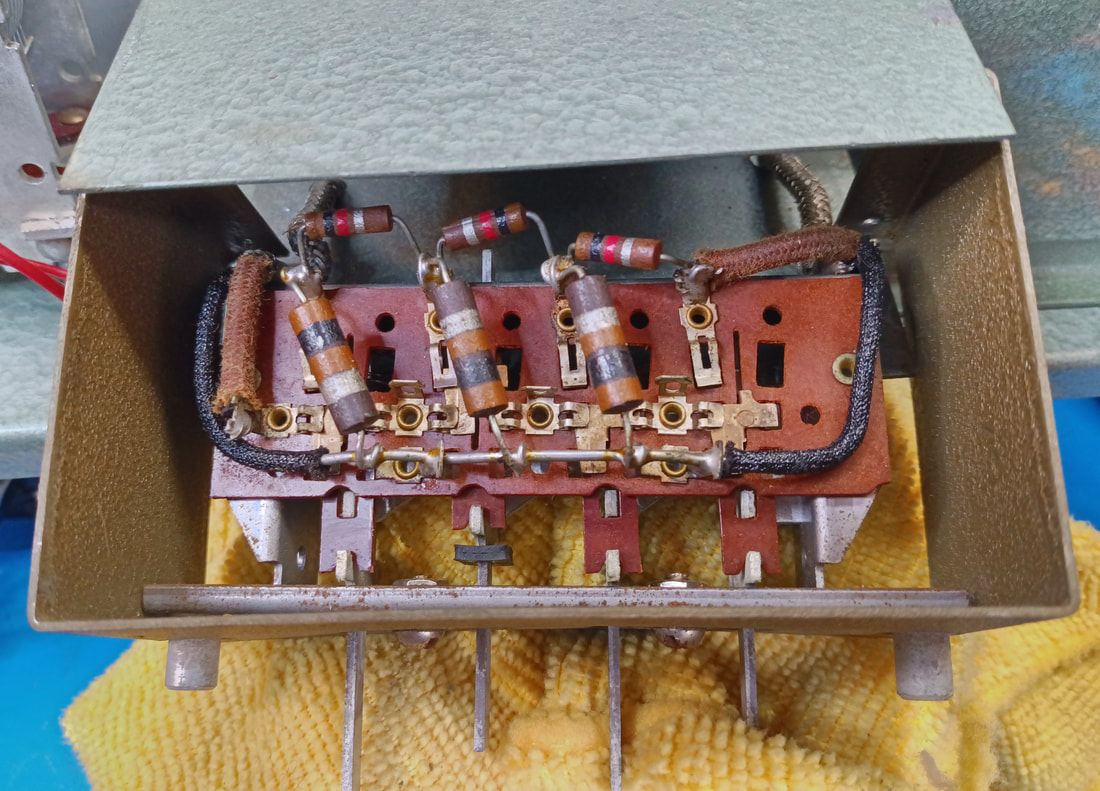

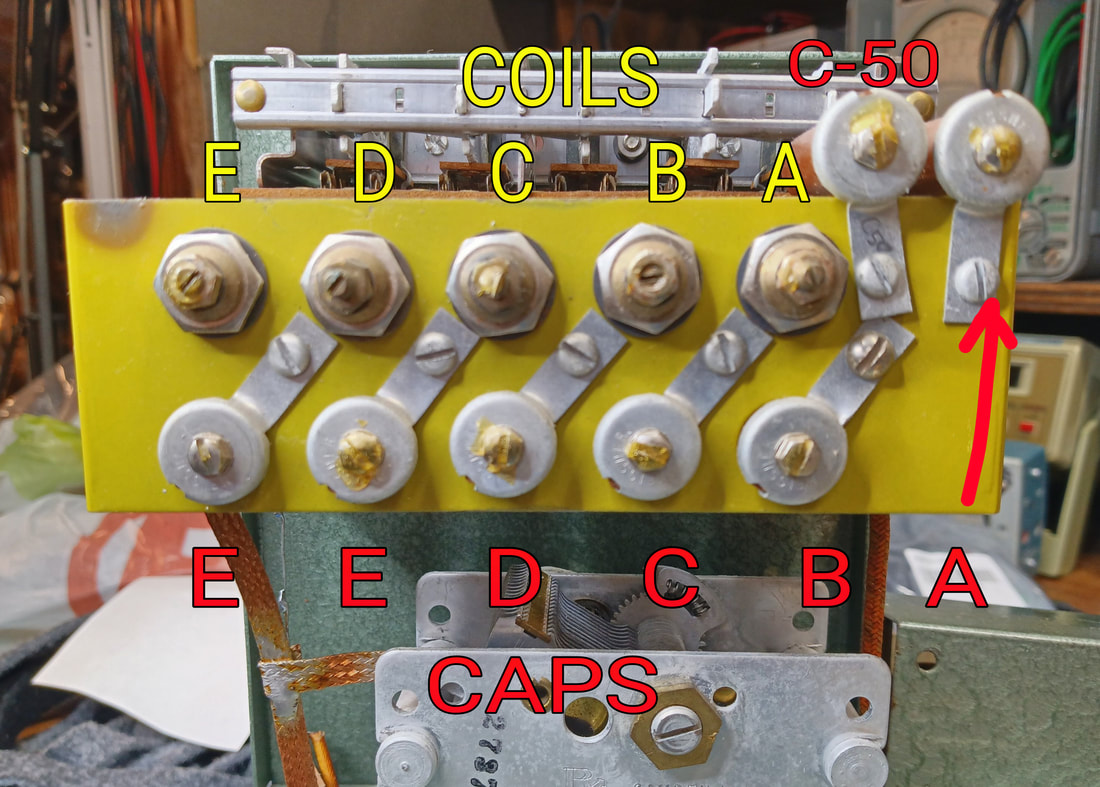

The band coil and trimmer capacitor layout is slightly different from the 561.

Supreme moved the "A" band trimmer capacitor from the chassis, where it was in the 561, up to the RF section with the other band trimmers. Also, the C-50 trimmer capacitor, which was not installed in my 561, is mounted beside the "A" trimmer. The trimmer C-50 across the main RF tuning capacitor is not in the alignment procedure and I'll just leave it as is unless there's an alignment issue. |

|

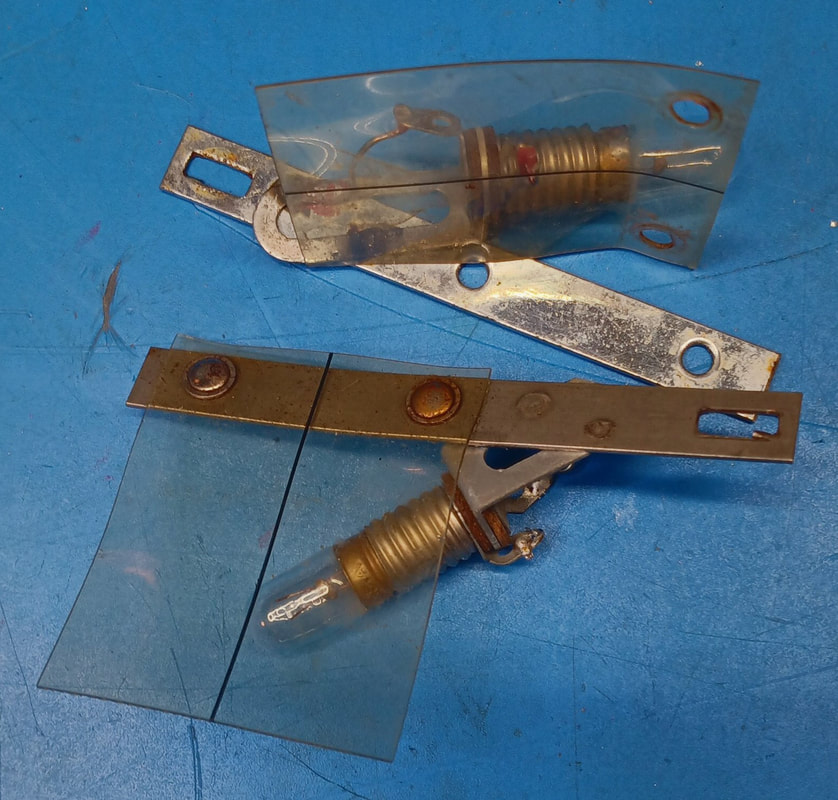

The top of the chassis is finished. Everything has been cleaned and all the tubes were given a quick check on my EMC model 200 tube tester. I also installed the new hairlines I made.

I ran into a small issue with the Audio Zero trimmer capacitor. It is a bit different physically from the one in the model 561 and when its connection terminals face the tuning cap as it was originally mounted, the audio frequency dial rubs on it. To fix this I rotated it 180°, but I had to run longer connecting leads since the terminals now face away from the tuning capacitor. |

|

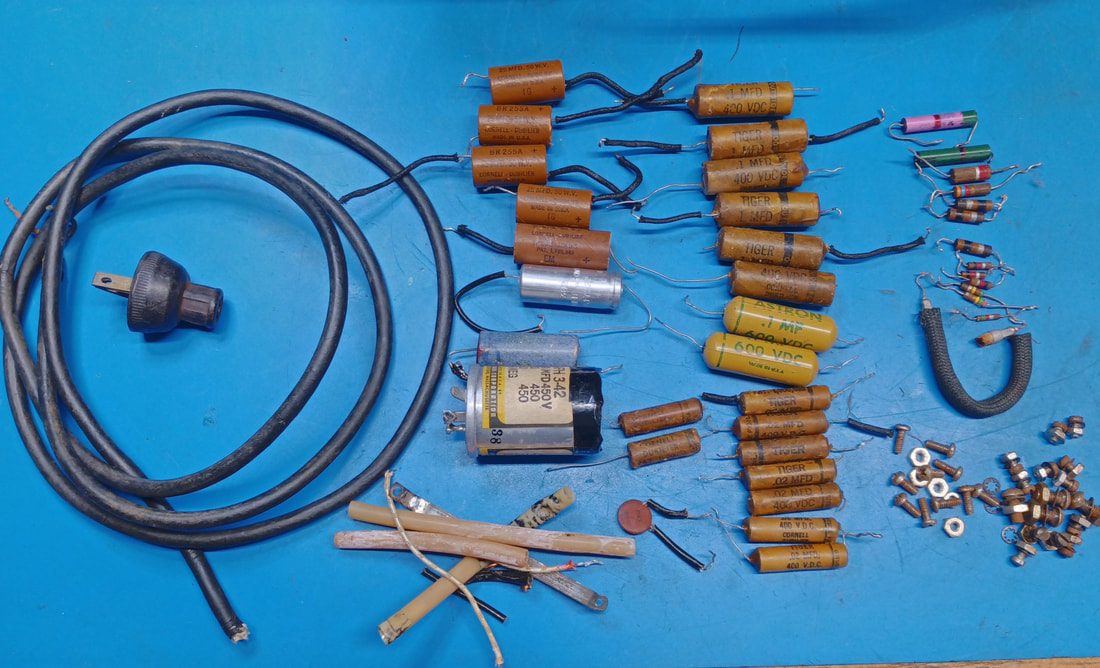

A summary of parts replaced includes

17 resistors, 26 capacitors and the 2 dial hairlines. All rusty screws, washers and nuts have been changed out, a new shielded power cord installed, and a fuse has been added along with a polarized power plug. One of the two yellow plastic encapsulated Astron capacitors checked very good on the Heathkit capacitor tester, but the second one shows a small amount of leakage, so I replaced both just to be safe. |

|

The front panel is finished, too. I just need to align the dials during calibration. This generator didn't come with any cables, but I have the two from the 561 for testing. The audio dial alignment mark should be set approximately 1/4" to the right of its hairline according to the alignment instructions.

I also have two new old stock plugs to make test cables for this generator, but I don't have the back shells, so I'll probably have to make those if I can't locate any. Apparently these connectors are the same as vintage Ford automotive speaker plugs. |

The alignment procedure for model 561 also works with the 666, and the RF alignment just needed the band ends tweaked. I was surprised how close the original band alignments were even after replacing all the bad components, removing and reinstalling the dials, and replacing all the rusty lock nuts on the band coils. I did have to adjust C-50 to give the trimmer for the top of Band E enough adjustment range. And the main RF tuning capacitor was a bit intermittent when fully meshed, causing the oscillator to drop out mostly on the low end of Band E, but cleaning and lubing its pivots fixed it.

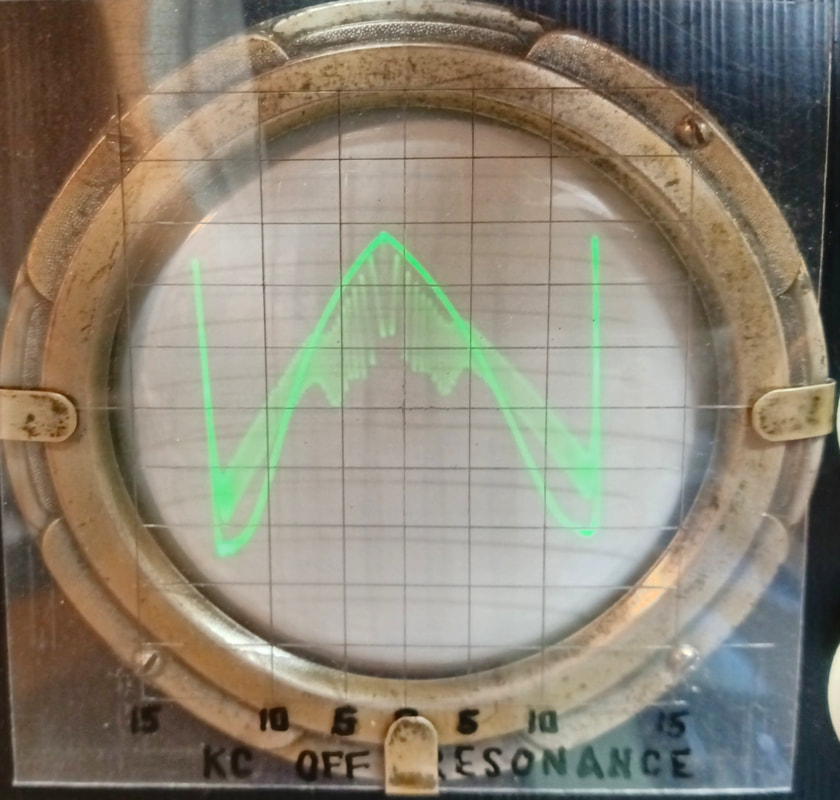

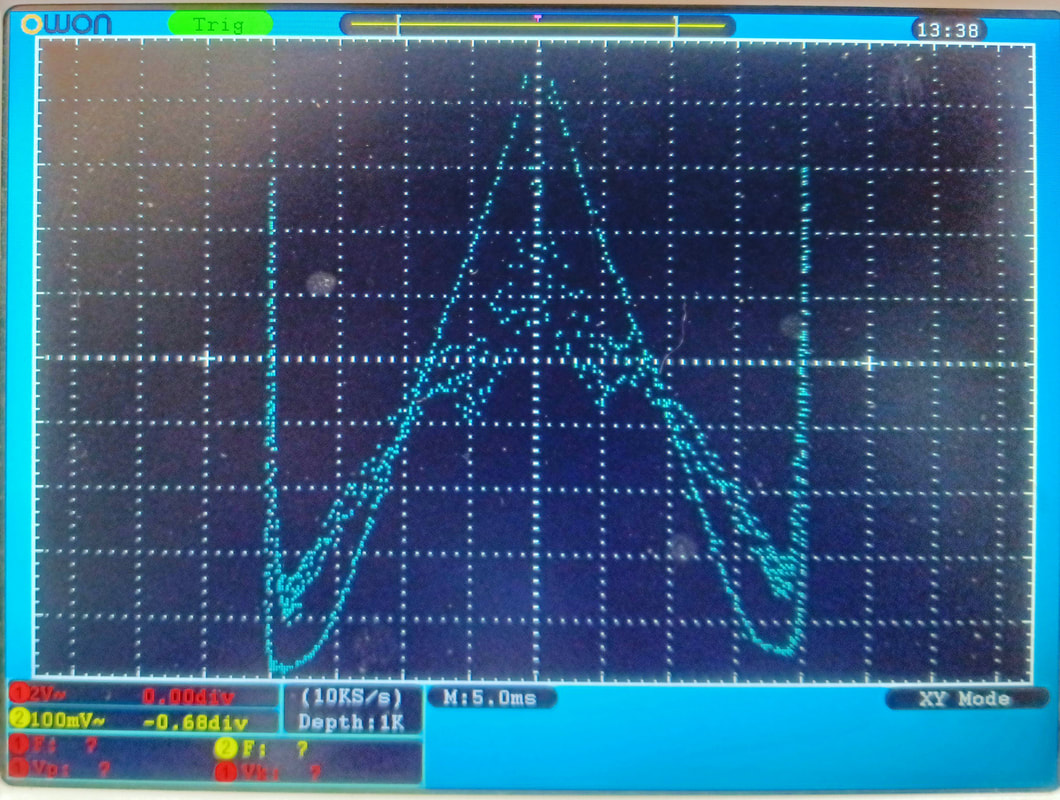

The photos are from the frequency modulator alignment. On the left is the curve displayed on the model 560-A Vedolyzer and on the right is the same curve as rendered on a digital oscilloscope.

The adjustment trimmer (R55) for the percent of modulation had been replaced with two 100Ω resistors in series, but I reinstalled a 1KΩ pot and then calibrated it.

I set up the RF generator to 200KC on Band A and adjusted the Carrier Level control to 100,000 microvolts RMS out using a digital oscilloscope. Then R34 in the RF Voltmeter circuit was adjusted to calibrate the Carrier Level mark on the meter.

The AF alignment is just setting the fixed oscillator to 209.5KC and then zeroing the variable oscillator to it at the zero mark on the dial, and with the "Zero Audio" trimmer capacitor set at half capacity. The dial alignment is not super accurate but is just fine for radio repairs. I have three of these Supreme BFO audio oscillators and none of them reads very accurately on the AF dial.

The photos are from the frequency modulator alignment. On the left is the curve displayed on the model 560-A Vedolyzer and on the right is the same curve as rendered on a digital oscilloscope.

The adjustment trimmer (R55) for the percent of modulation had been replaced with two 100Ω resistors in series, but I reinstalled a 1KΩ pot and then calibrated it.

I set up the RF generator to 200KC on Band A and adjusted the Carrier Level control to 100,000 microvolts RMS out using a digital oscilloscope. Then R34 in the RF Voltmeter circuit was adjusted to calibrate the Carrier Level mark on the meter.

The AF alignment is just setting the fixed oscillator to 209.5KC and then zeroing the variable oscillator to it at the zero mark on the dial, and with the "Zero Audio" trimmer capacitor set at half capacity. The dial alignment is not super accurate but is just fine for radio repairs. I have three of these Supreme BFO audio oscillators and none of them reads very accurately on the AF dial.

|

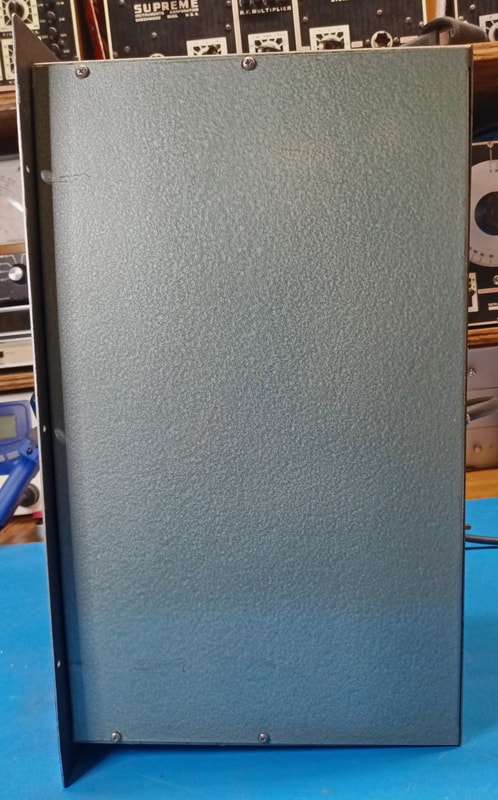

Starting to reassemble the generator by reinstalling the bottom plate. This is the first piece of Supreme gear I've owned that has a cover plate on the chassis. I suppose by around 1950 they were getting just a little more safety conscious.

The screws to mount the bottom plate and secure the generator in the cabinet are all Philips head, which I think could be original since by around 1950 they would have been more commonly available. But all the front panel assembly screws are still fillester head same as on their older equipment. |

It's back in its cabinet and ready to go. I'm not sure what I'll do with this generator since I already have a model 561 on my workbench. For now I guess it will go on a display shelf beside my extra model 560 Vedolyzer and model 562 Audolyzer, the two instruments it was meant to be paired with.

Page created 6/1/2023

Last updated 7/8/2023

Last updated 7/8/2023