Saving a Supreme Model 562 Audolyzer from the Scrap Pile

|

As found this Audolyzer was in very poor condition. Going by its serial number of 2443, and a note on the 1946 schematic, plus the color of its face plate, the audio jack style, and descriptions in the 1946, '47 and '48 catalogs, I think this 562 was manufactured sometime around 1946. That makes it over 75 years old. It is more or less complete inside, but not all the components are original. Mostly I am restoring this unit to save it from being scrapped for its parts, and because I want to practice restoring a front panel.

|

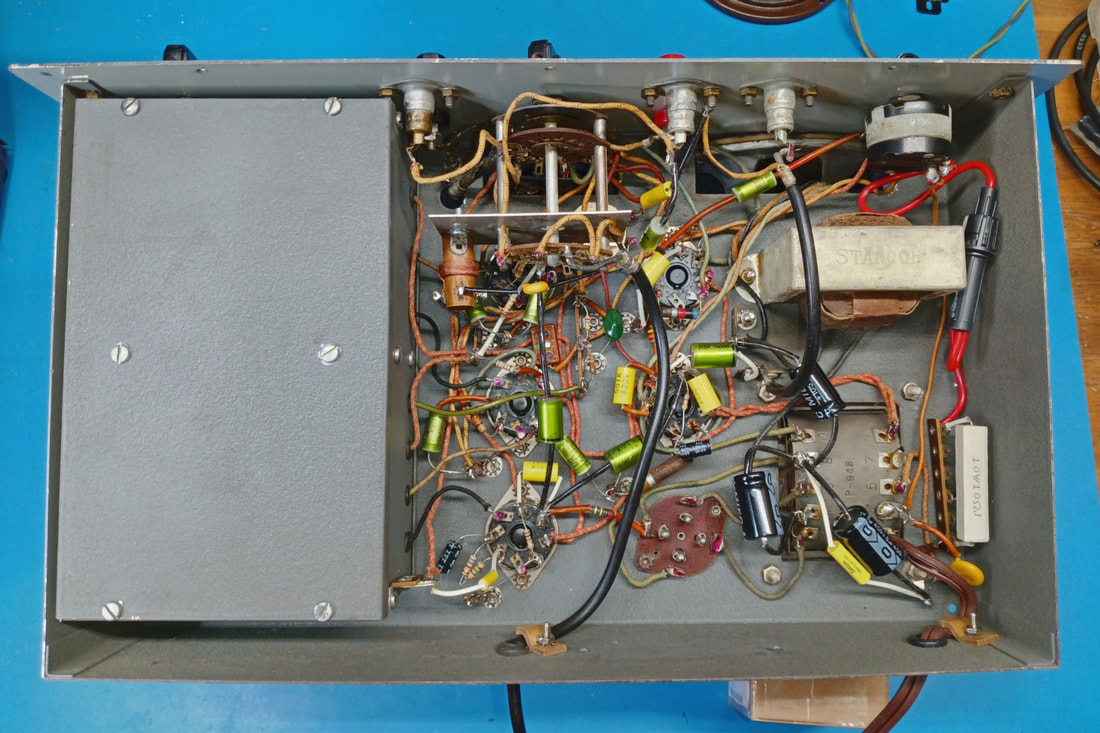

It has obviously been worked on in the past, looks like at least a couple of times. The older repair work was mostly well done, but someone in more recent times was trying to troubleshoot it by snipping leads, tack soldering components and generally making a mess of it.

Just wiggling some of the resistors and capacitors was enough to break the leads free. Real poor work, but it was easy to remove some of the old components.

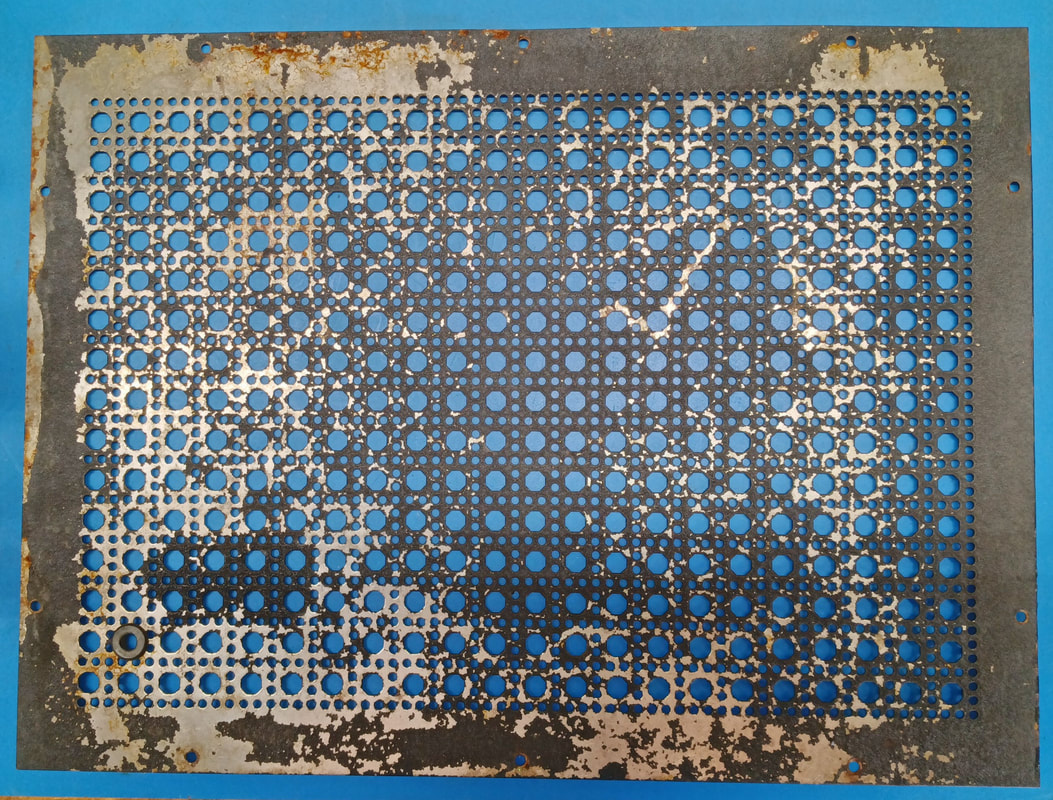

The worst problem of all is the paint is literally falling off the front panel. There's also a lot of rusty areas on the chassis, but the chassis can probably be touched up. However, the front panel is too far gone and will have to be recreated from scratch.

Just wiggling some of the resistors and capacitors was enough to break the leads free. Real poor work, but it was easy to remove some of the old components.

The worst problem of all is the paint is literally falling off the front panel. There's also a lot of rusty areas on the chassis, but the chassis can probably be touched up. However, the front panel is too far gone and will have to be recreated from scratch.

|

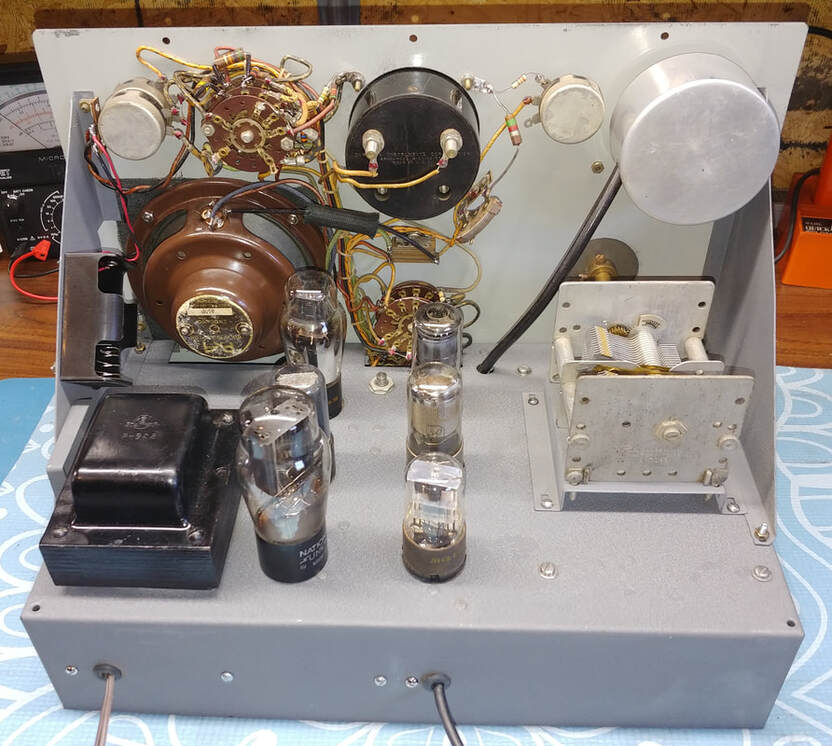

The chassis removed from its wood cabinet. The cabinet is falling apart at the joints and needs to be reglued and refinished. The chassis is dirty but it's not in real bad condition except for the rusty areas. Not the worst I've ever seen and at least the paint isn't falling off the chassis like it is on the front panel. There was also a battery for the ohmmeter on the left side where it's rusted and the metal strap that held the battery is also very rusty.

|

The chassis is painted in the same gray wrinkle finish as the front panel, a little better quality than just a plain metal chassis. Some older Supreme gear had chromed chassis before they switched to painted ones. My older black 562 has both, a chromed chassis that was painted in wrinkled black at the factory.

The tube complement, starting with the glass tubes, from front to back, are a 6J5 for the VTVM, a 6V6 audio output and the #80 full-wave rectifier. On the metal tube side the first two are 6SG7 RF amplifiers and then a 6SQ7 detector and 1st audio amp. The schematic shows two 6SK7 tubes in the RF amps but the 6SG7 is a valid substitute.

The tube complement, starting with the glass tubes, from front to back, are a 6J5 for the VTVM, a 6V6 audio output and the #80 full-wave rectifier. On the metal tube side the first two are 6SG7 RF amplifiers and then a 6SQ7 detector and 1st audio amp. The schematic shows two 6SK7 tubes in the RF amps but the 6SG7 is a valid substitute.

|

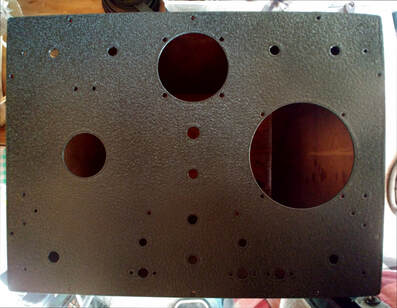

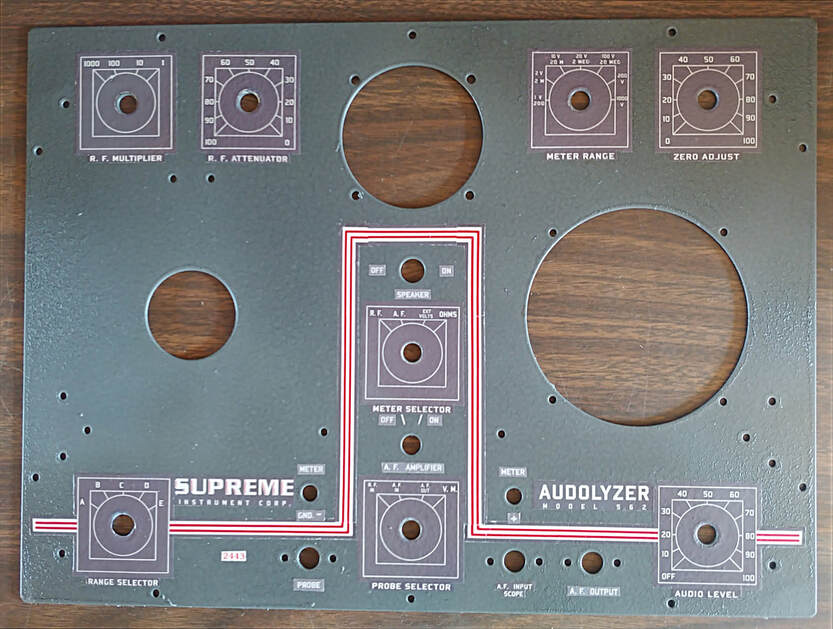

The front panel removed from the unit. Every time I touch it more paint falls off. I need to scan it before I lose too much paint so I can recreate the dials and lettering on my computer. The plan is to create water slide decals to relabel it.

The top left corner is bent, apparently from having been dropped. The oak cabinet corner isn't damaged so it must have been out of the case when it happened. It will get straightened when the panel is repainted because if I do it now more paint and lettering will fall off. |

|

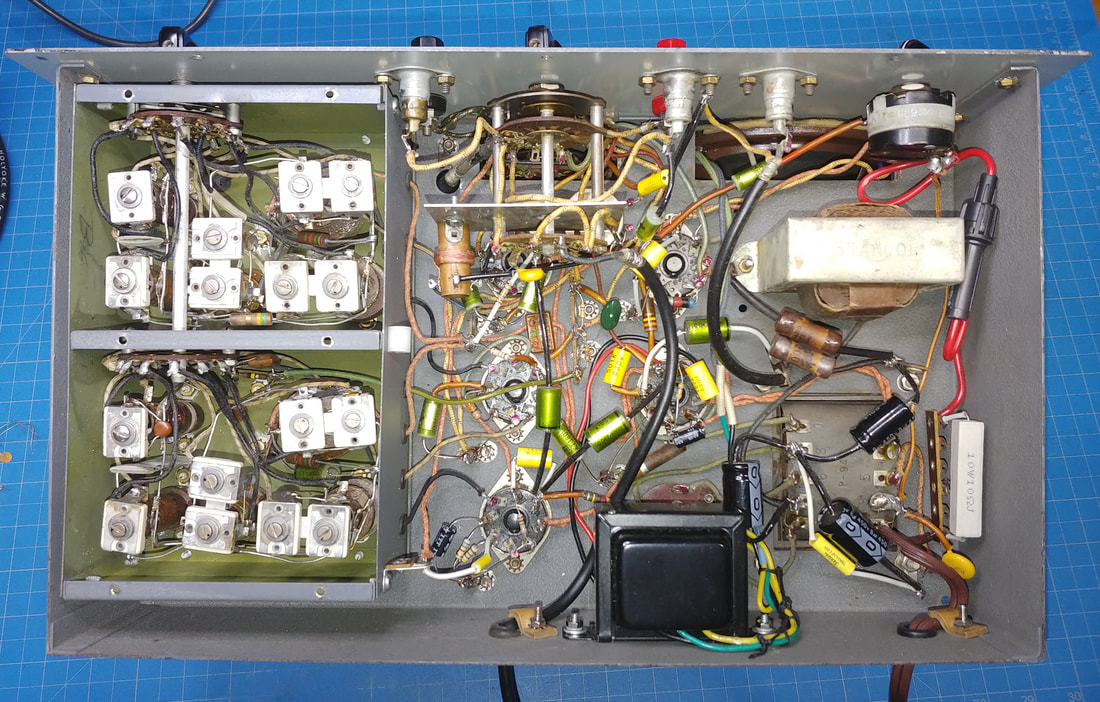

Under the chassis is clean but there's a lot of paper and electrolytic capacitors to replace. There are 22 paper caps in all plus 5 electrolytics. The shielded box contains the band coils and trimmer caps for the receiver plus several of the paper caps and resistors.

All the resistors need checked, and since they are the older uncoated style, it's a good bet some will need replaced. The input and output jacks are oddball Motorola-style antenna jacks as used on automotive radios. On Audolyzers from 1941 to about 1946 the two jacks were 1/4" phone jacks, and the probe was wired directly into the set. |

|

The top of the chassis cleaned up nicely and I found an off-the-shelf spray paint that was a close color match to the original gray finish. The rusty spots were treated with rust remover, then paint was sprayed into a cup and brushed on with a small, stiff brush. The touched up spots were dry brushed into the existing finish and it came out much better than expected. The touched up areas looked so good I ended up dry brushing the whole chassis top.

It looks like, from careful examination of the wrinkle finish, that there are small pin holes in the wrinkled paint that let rust get a foothold. Brushing the chassis sealed up any remaining holes. |

|

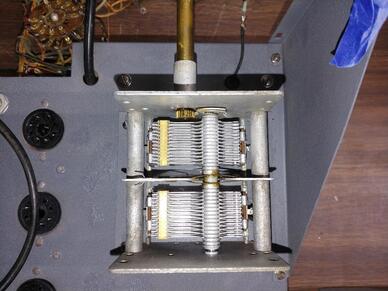

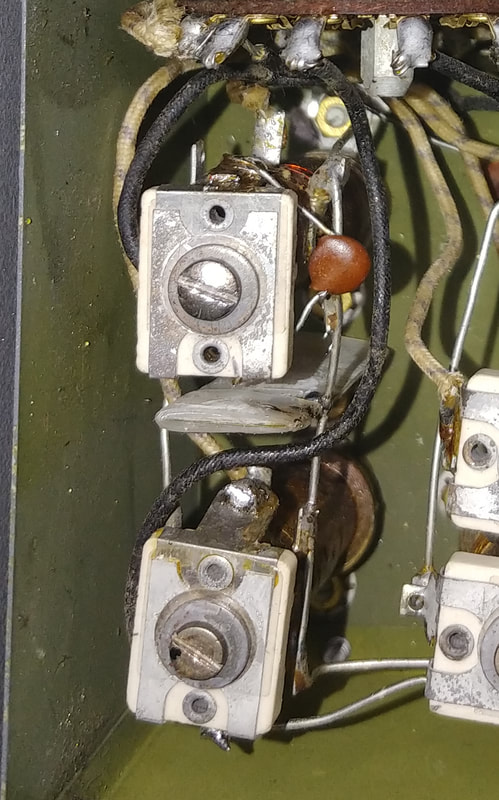

Inside the shielded compartment are the band coils and trimmer capacitors for the TRF receiver. There's also three paper capacitors to change and several resistors. Only two of the resistors were out of spec, both are labeled 1500-ohms on the schematic but were actually 1600-ohm resistors in this unit. They are visible in the center of each half of the box.

The TRF receiver has two RF stages, a detector and then two AF stages. It tunes from 95Kc to 14.5Mc which covers the common IF frequencies, as well as a wide range of AM and shortwave oscillator frequencies. It also has an antenna input coax in the rear to use it as a radio. The antenna is connected to the receiver RF input when the PROBE SELECTOR is in the AF OUT position. The radio's audio output from the first audio amp is then routed to the test probe, and also to the 6V6 audio amplifier driving the speaker and AF OUT jack. The output of the probe can be used as an input source to test audio circuits or you can just listen to the radio. |

I removed the variable capacitor and cleaned it with a concentrated spray cleaner. It came out almost as shiny and clean as new. The cleaner is also a degreaser so I sprayed the capacitor down with WD-40 afterwards to protect the bare metal, and then I relubed the bearings.

The RF Multiplier switch has two paper caps to replace. The hardest part was just getting the cover off. In the early schematic there are three capacitors on the switch. The 0.15uF for the 1000 position was removed in the later schematic and that switch position grounded. Not sure if that was just a cost savings move, or what, so I added the capacitor back to see if it made a difference in the input signal level for that switch position. But after testing I really didn't see any change in signal levels. It just seemed illogical that one of the inputs should actually be grounded.

I also noticed several resistors that don't match the schematic, such as substituting a 360KΩ resistor where the schematic calls for a 350KΩ, or a 910KΩ for a 1Meg. I wonder if Supreme might have had a large stock of certain values and tried to use them wherever possible, or if it's just a case of material shortages from the war?

The RF Multiplier switch has two paper caps to replace. The hardest part was just getting the cover off. In the early schematic there are three capacitors on the switch. The 0.15uF for the 1000 position was removed in the later schematic and that switch position grounded. Not sure if that was just a cost savings move, or what, so I added the capacitor back to see if it made a difference in the input signal level for that switch position. But after testing I really didn't see any change in signal levels. It just seemed illogical that one of the inputs should actually be grounded.

I also noticed several resistors that don't match the schematic, such as substituting a 360KΩ resistor where the schematic calls for a 350KΩ, or a 910KΩ for a 1Meg. I wonder if Supreme might have had a large stock of certain values and tried to use them wherever possible, or if it's just a case of material shortages from the war?

|

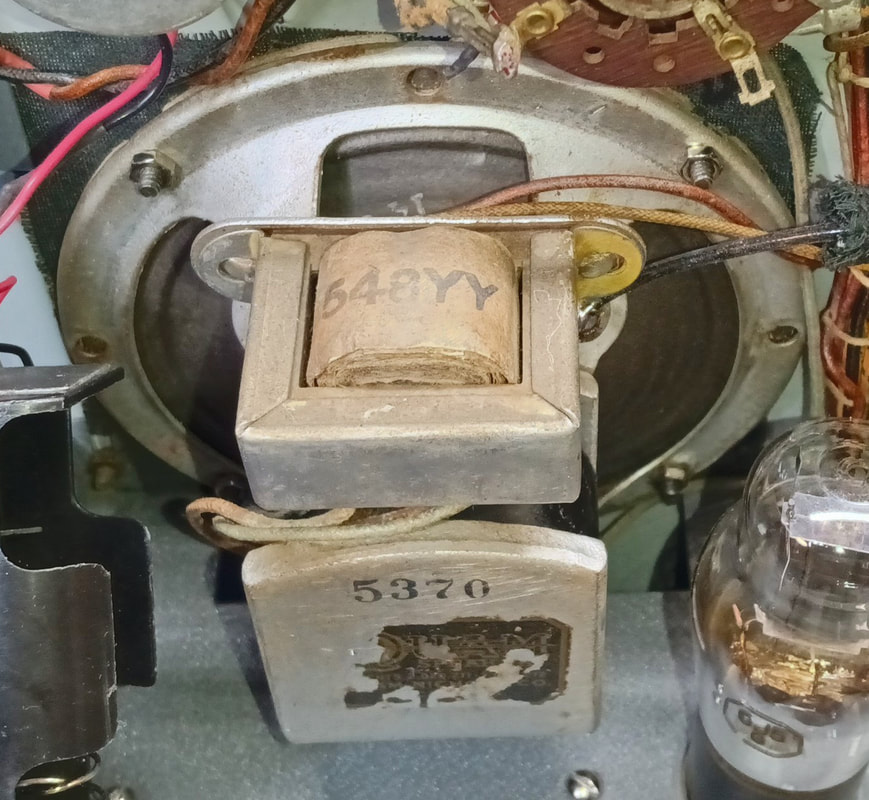

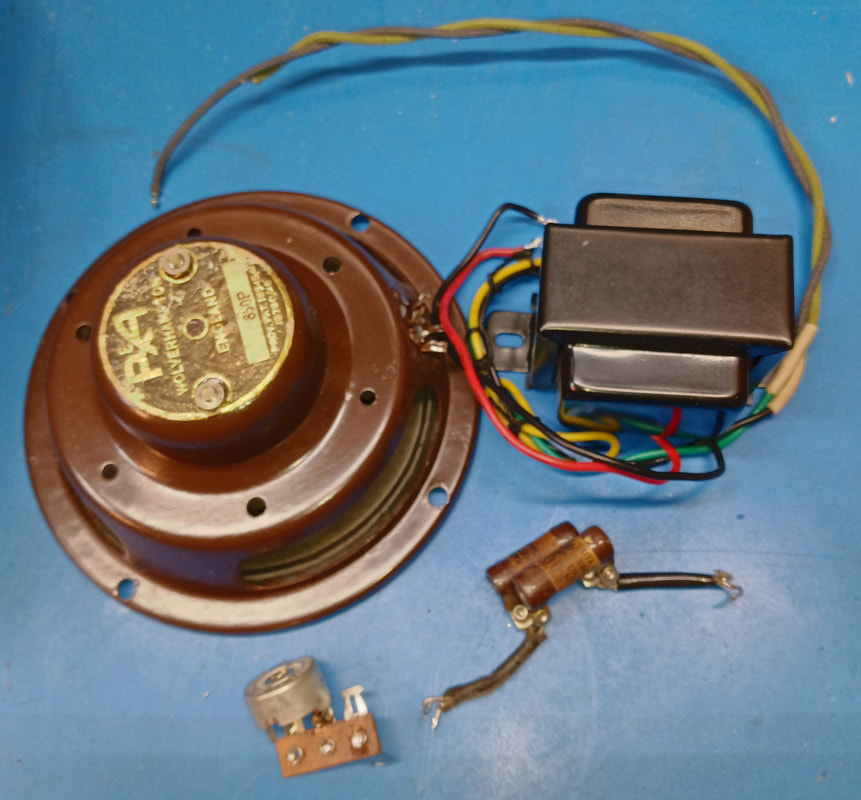

The speaker is an R&A brand and the label says made in England. It is not original and the schematic shows a speaker with a field coil, not a permanent magnet.

Also the output transformer was hanging from it by just a single screw, not something the factory would do. And looking under the chassis revealed the wires from the transformer to the 6V6 had been cut and spliced, so the transformer is not original either. It looks like the speaker and transformer were changed a long time ago though, because the spaghetti tubing on the splices is dry rotted. |

The speaker's field coil is labeled as 1000Ω on the schematic and has been replaced in the power supply with two 2000Ω power resistors in parallel.

I found an ad online for this R&A speaker, and it dates back to the 1960's, so this repair/replacement is about 50 years old.

I found an ad online for this R&A speaker, and it dates back to the 1960's, so this repair/replacement is about 50 years old.

|

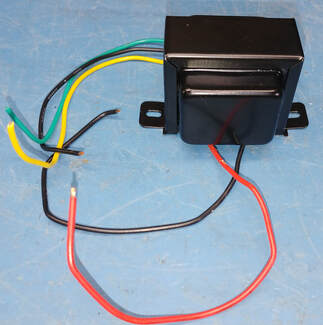

The old, non-original audio transformer is very small and not a good match to the 6V6 so I ordered a replacement designed specifically for a 6V6. It's has more than twice the iron as the old transformer and is mounted to the rear panel under the chassis where the box containing the power supply filter capacitors was originally mounted. The transformer drops right in and matches the pre-punched holes perfectly.

The new transformer is rated at 5 watts and has a primary winding impedance of 5000 ohms to match the 6V6, and a DC resistance of 500 ohms, exactly what's on the schematic. The replacements will work fine, but I'll keep looking for an original speaker and audio transformer so I can return the chassis to its original condition, if possible. |

The oak cabinet joints were reglued and then it was sanded, stained and coated with clear satin enamel. The original handles were missing and replaced with "screen door" handles from the hardware store.

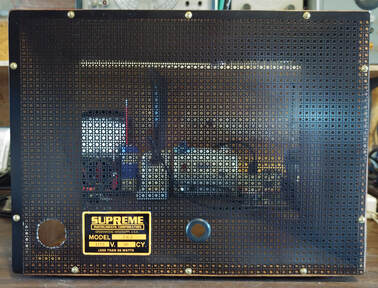

The metal back panel was also missing and a new one was cut from a decorative metal panel. Holes were added for the power cord and antenna coax cable and I made a reproduction power spec label. I cut the power cord hole large enough to get the plug through and ordered a large grommet for it. It's not an exact match for an original back but close enough. It buttons up the rear and still allows for good ventilation, but I'll also look for an original back, too.

The metal back panel was also missing and a new one was cut from a decorative metal panel. Holes were added for the power cord and antenna coax cable and I made a reproduction power spec label. I cut the power cord hole large enough to get the plug through and ordered a large grommet for it. It's not an exact match for an original back but close enough. It buttons up the rear and still allows for good ventilation, but I'll also look for an original back, too.

|

I converted an old probe found in a junk box for use with the Audolyzer. I replaced it's original internal resistor with a 100KΩ, and changed the connector on the cable to a Motorola-type. The probe end is a two-piece affair, it must have originally had interchangeable tips, but the others are long lost. It uses the same antenna-style connector to plug the two halves together.

One of the advertised advantages of the Audolyzer was that a single probe was used for troubleshooting a radio from antenna coil to voice coil. You didn't have different probes for RF, AF or the VTVM like on a Rider Chanalyst. |

But using the probe with the VTVM is optional, a set of regular test leads connected to the meter jacks can also be used, while using the main probe for a different function at the same time. Ohms measurements are also made using test leads connected to the meter jacks.

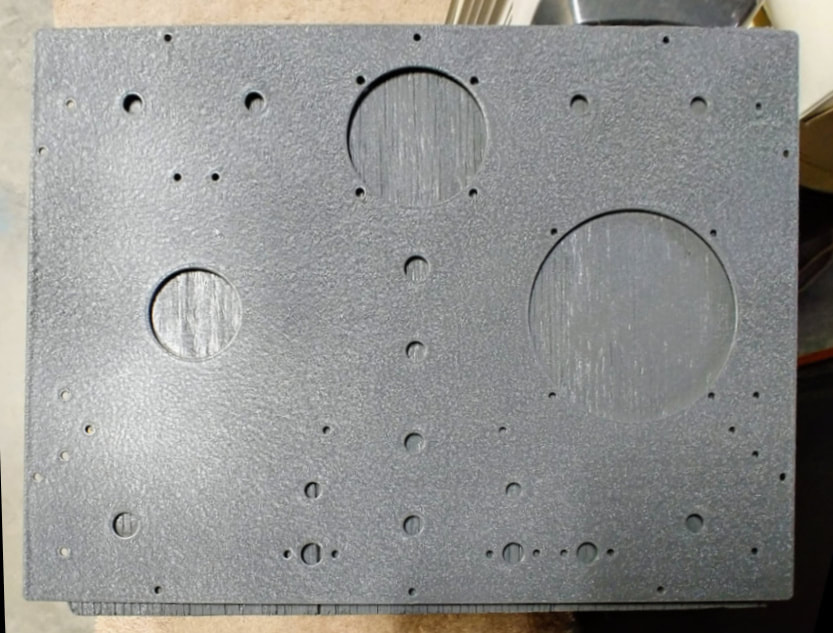

The front panel was stripped and repainted in a black wrinkle finish. I like the black finish but decided to recolor the panel gray as it was originally, and so it matches the chassis. The wrinkle paint is VHT brand and available at auto stores. VHT also makes gray wrinkle paint but it was not available locally.

I've found a couple of fonts that are pretty close to the Supreme lettering so now I can recreate the dials and print them on water slide decal paper. I also found a couple of products called Microsol and Microset to "melt" the decals onto the wrinkled surface of the panel.

I've found a couple of fonts that are pretty close to the Supreme lettering so now I can recreate the dials and print them on water slide decal paper. I also found a couple of products called Microsol and Microset to "melt" the decals onto the wrinkled surface of the panel.

|

All the new decals are on. That was a lot of work. It's not perfect but I'm still very pleased with how it came out. After the labels dried the panel was coated with multiple coats of clear matte enamel spray to protect them.

Matching colors of the decals was a nearly impossible task. They are one shade of gray on screen, and another shade when printed and applied. Plus I printed several sheets and each sheet is a little different. The matte spray also seemed to tone down the labels some. In the end they are close enough for me. And my phone camera exaggerates the color difference between panel and labels. |

|

Some assembly required, but it's looking like an Audolyzer again. It was taken down to the point where putting all the pieces back together was almost like building a kit. During reassembly all rusty hardware was replaced with new, except the black oxide fillester head screws on the front panel, which are hard to find so were cleaned and reused. The nuts and washers for the front panel controls and switches were also replaced. It looks so nice I can't wait to get it powered up.

|

|

The chassis is all back together and instead of reusing the metal tubes I installed a full set of glass tubes, just for looks. Also, on the left side plate I added a "D" cell battery holder for the ohmmeter. Hardly looks like the same unit now.

The three lowest ohmmeter ranges are powered by only the 1.5-volt battery and can be used even when the Audolyzer is turned off. So I was able to test them already and all three work fine. Readings are well within the tolerance of the divider resistors. |

|

As soon as the face plate was back on the chassis I finished replacing the last of the paper capacitors, a few more resistors, and reconnected some loose wiring. So far I have replaced 30 resistors, 22 paper capacitors and 5 electrolytic caps, plus one of the original metal tubes was bad, and I installed a new audio transformer. I also made a new clear plastic dial index hairline.

|

|

Since I decided not to replace the Motorola connectors, I made a shielded adapter cable for connecting a scope or patching audio in or out of the Audolyzer. The other probe is the main probe I made earlier, which is used for testing RF, IF and AF circuits, and for voltage measurements. That's it for cables and probes except for a simple set of meter leads for use with the ohmmeter and also with the voltmeter in the Ext. Volts setting.

|

|

The 1946 schematic with the 5Y3 rectifier says the B+ should be 250VDC. However, the older 1939/1940 schematic with a #80 rectifier shows the B+ as 270VDC. In this unit with its older #80 rectifier, the B+ is 269VDC with the variac set for an AC line voltage of 117.5VAC as specified on the rear panel label.

At full line voltage the B+ is 284VDC. It reads high because my line voltage is 122 - 125VAC. |

For safety I added a fuse to the AC line using a pigtail fuse holder so I wouldn't have to drill a hole in the chassis. And while I was at it I inserted a 10-ohm power resistor to lower the line voltage to the transformer primary back down to 117VAC, just like in the good 'ol days.

|

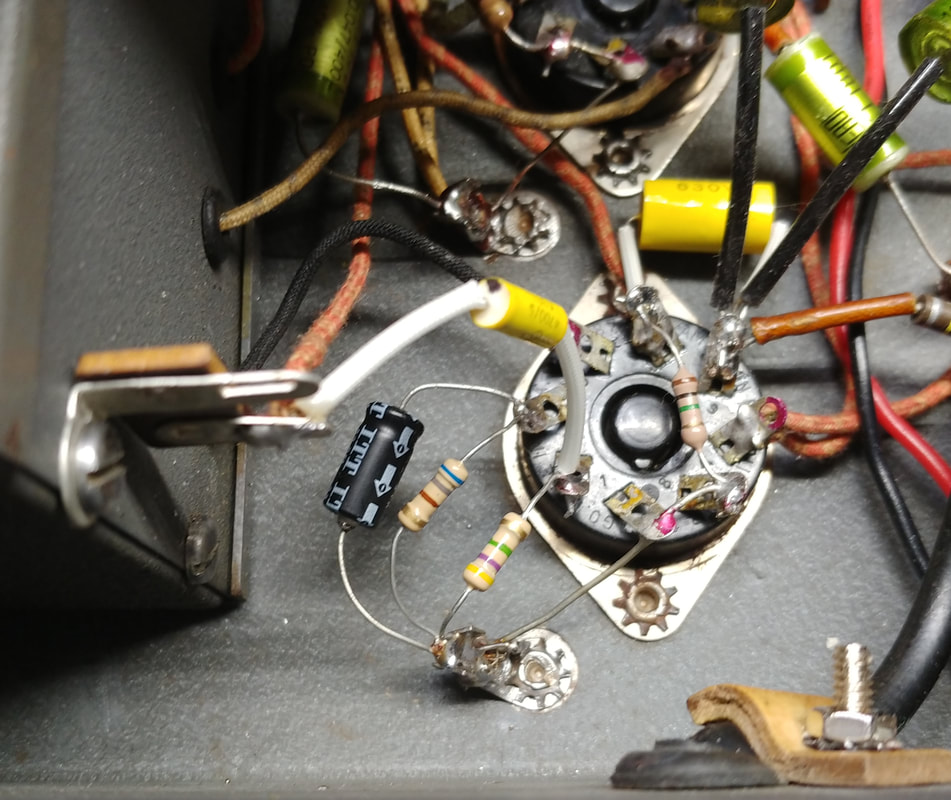

To align the voltmeter there are three controls. Adjusting three potentiometers at once sounds like a recipe for insanity, so I set the front panel Zero Adjust (R43) to 50 and left it there. Then I connected a 1-volt source to the meter (on 1-Volt scale) and adjusted the 1K control (R42) in series with the meter to read +1 volt. Next I reversed the 1 volt source and checked the negative reading, tweaking the chassis mounted control (R44) to set it. Changing one setting affects the other so I repeated these steps until the meter read 1 volt in both directions and I only touched R43 when adjusting R42 and R44 no longer brought the needle any closer to center zero.

|

The meter zero kept drifting on me so I replaced trimmer R42. Looks like the metal bands crimping the ends of the trimmer's nichrome wire are rusty and not making good contact. However, later on I was able to clean the rusty bands with a spray rust remover which allowed me to reinstall the original.

|

There are no alignment instructions in the manual for the TRF receiver. The coils are not adjustable, but normally trimmer capacitors are adjusted at the high end of the band where they have the most effect. For Bands A, B, and C there are both parallel and series trimmers, but bands D and E have only a single parallel trimmer.

I adjusted the parallel trimmers on the coil forms of bands A, B and C to align the dial frequency and then the series trimmers to peak up the signal. After adjusting each series trimmer I had to scan the band for oscillations. If oscillations were occurring I detuned the series trimmer of the second RF amplifier for that band just enough to completely eliminate it. It didn't take a lot of adjustment and I did not find it necessary to readjust any other trimmers to stop the oscillations. |

Other alignment issues included:

- on the bands with both parallel and series trimmers (Bands A, B and C), the two trimmers interact. If a trimmer wouldn't peak (all open or tightened down) then I backed off both trimmers a turn or two and started again with the parallel trimmer.

- The tuning capacitor's range is wider than the dial scales and turns past both ends of the scales, which raises the question of where it should be initially aligned with respect to the dial's hairline. I finally decided to align it with the dial line at the lower end of the bands, and that seems to work.

- on band E fully tightening the trimmer did not allow me to peak the signal. I added a 10pF NPO capacitor across the trimmer and then was able to peak it. Possibly the inductance of the coil has changed due to moisture over the last 75 years.

- on the bands with both parallel and series trimmers (Bands A, B and C), the two trimmers interact. If a trimmer wouldn't peak (all open or tightened down) then I backed off both trimmers a turn or two and started again with the parallel trimmer.

- The tuning capacitor's range is wider than the dial scales and turns past both ends of the scales, which raises the question of where it should be initially aligned with respect to the dial's hairline. I finally decided to align it with the dial line at the lower end of the bands, and that seems to work.

- on band E fully tightening the trimmer did not allow me to peak the signal. I added a 10pF NPO capacitor across the trimmer and then was able to peak it. Possibly the inductance of the coil has changed due to moisture over the last 75 years.

|

One issue I found was with the TRF's sensitivity. The input to the first RF amp does not match the schematic. According to the schematic there was originally an RF coil from grid to ground, but in this set it has been replaced with a 100KΩ resistor. I don't know if that was factory or not.

The coax for the antenna input goes through a capacitor and straight onto the grid of the first RF amplifier, but connecting the coax directly to the grid is killing the sensitivity. In an old radio magazines there is an article on updating old TRF receivers and that addresses how to connect the antenna to the RF amp in a TRF. Their fix is to add an untuned, tapped coil to the grid input, and attach the antenna to the tap, similar to what the Supreme schematic showed, except for the tap. |

To fix the issue I added a tapped coil to the grid circuit and removed the existing 100K resistor. The coil is an AM radio oscillator coil that I already had on-hand and I connected the tap to the capacitor coming from the coax center conductor. It works very well and the receiver is quite sensitive now. I didn't have this problem with my black Audolyzer, but it still had its original coil on the 1st RF grid.

|

Another issue in this set is coil shielding. On an antique radio forum I read a post that claimed the Audolyzer's coils are mounted too close together which allows the band coils of the selected band to couple with the coils of the next lower band, causing portions of the band to go dead because the lower band coils are absorbing signal from the active coils. The fix mentioned was to short out the lower band coils by adding a switch wafer to the band switch just for this purpose. I tested each band to see how bad this effect is, and really only found the problem affecting band E on this set.

I decided a simpler way to fix the problem was by adding shielding made from pieces of brass sheet, insulated in heatshrink, between the two sets of coils for bands D and E. After a bit of experimenting to adjust the shield positions, I soldered them to the ground bus wire of the coils. Sliding the shield closer to the coil for band E provided the best isolation. I insulated the brass sheets because the bare bus wire on the left side of the coils is B+. |

|

Another change I made to the receiver was to fix the very low, distorted audio out of the detector that I was experiencing for weak signals. This may not have been an issue for Supreme since their troubleshooting methods used a signal generator and all that's needed with it is to turn up the output a bit. But by lowering the value of the 2200Ω cathode resistor on the 6SQ7 to 680 ohms, the detector audio is no longer distorted and the receiver detects weaker signals.

|

After the repairs and modifications the TRF receiver does quite well. The selectivity is a bit wide, to be expected from a TRF I guess, but the sensitivity is good and I can pull in lots of shortwave stations, and AM DX at night, with just a 20-foot piece of wire hanging out a window. And the audio fidelity is better than the average AA5.

Now that the TRF receiver is aligned and has some sensitivity, it's time to see how the Audolyzer works as a test instrument. I was restoring a 1936 Sears Tombstone radio which gave me the perfect opportunity to test the Audolyzer's capabilities. As I tested the radio I quickly discovered the TRF receiver is sensitive enough that just tuning in the radio's IF on the Audolyzer, and then bringing the probe near the IF stage, sounds like you just tuned in the radio's station on the TRF's dial. I guess it's good they have an attenuator on the front panel. It's certainly sensitive and should prove handy for some "rapid radio repair".

Now that the TRF receiver is aligned and has some sensitivity, it's time to see how the Audolyzer works as a test instrument. I was restoring a 1936 Sears Tombstone radio which gave me the perfect opportunity to test the Audolyzer's capabilities. As I tested the radio I quickly discovered the TRF receiver is sensitive enough that just tuning in the radio's IF on the Audolyzer, and then bringing the probe near the IF stage, sounds like you just tuned in the radio's station on the TRF's dial. I guess it's good they have an attenuator on the front panel. It's certainly sensitive and should prove handy for some "rapid radio repair".

|

Rapid Radio Repair is a reference to, and the name of, a small book written by radio repairman John D. Burke and published in 1950. It's an interesting little tome on how he used signal tracing to make a living in the radio repair business of the 1930's and 40's. His signal tracer was a Hickok Traceometer, but he actually modified it to be more like an Audolyzer by adding an audio amp and volume control to better hear the signal, and an audio input jack for audio tracing, all features of the Audolyzer. The Supreme Audolyzer could be used just as successfully with his rapid repair techniques and the book is available online as a free PDF download.

|

Updates to the Audolyzer

I finally found an original field coil speaker, audio output transformer, and metal back that someone had pulled from a junk Audolyzer, so now I can replace those non-original parts on mine.

|

The speaker was made by a company called Quam. It's in very good condition and the person who removed it was careful not to cut any of the wires short, so it was an easy install. Looks like the Supreme part number for it is 5370.

Also, the two power resistors that had been installed in place of the speaker field coil were removed. The audio output transformer is mounted right on the speaker and is also in good condition, so it replaces the one I installed under the chassis. Now all the major components are original again. |

|

A look under the chassis after the speaker install. The replacement audio transformer and the two 2000Ω power resistors have been pulled since they are no longer needed.

While testing the new speaker the audio amp started breaking into oscillation above about half volume, I removed the mod to the first audio amp to see if that was the cause, but it did not cure the oscillation and I also lost a lot of sensitivity to weak signals. I reinstalled the 680Ω cathode resistor, and moved the wire to the 1st audio grid to better isolate it, and now the oscillation is gone and the sensitivity is good again. |

|

The rear panel just needs a quick paint job and it's ready to go. I removed the metal model label before painting. Supreme threaded the power cord through one of the small holes in the panel before soldering it in. They did that on all the equipment I have that uses the vented rear panel, but previous owners got creative on most of them by punching holes or cutting slots to make the panel removable and not trapped on the cord.

|

Page created 12/7/2019

Last updated 12/4/2022

Last updated 12/4/2022