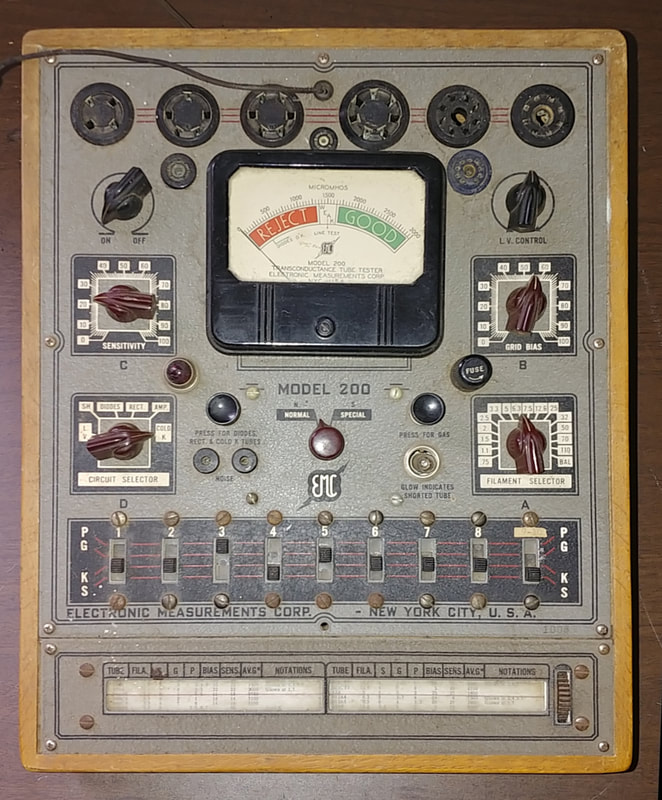

An EMC Model 200 Tube Tester Restoration

This mutual conductance tube checker was built by the Electronics Measurement Corporation of New York. It's a post war tester and can measure tube Gm in micromhos or give a quality measurement on an English Reading scale. And like most "modern" testers it can also check for shorts, gas and noise. There are sockets for early 4 to 7-pin large tubes, plus octal, loctal, Bantam Junior, and 7-pin and 9-pin minatures.

|

The exterior is in good shape, with just the usual dirt, rusty screw heads and such to deal with. The slide switches are difficult to slide and really need cleaned.

The roll chart is a separate unit from the tester chassis, which will make it easier to protect the roll during restoration. This chart is labeled as a model 206 chart, which was basically an upgraded version of this tester. It used lever switches for tube setup instead of slide switches, and had a micromhos range selector switch. |

|

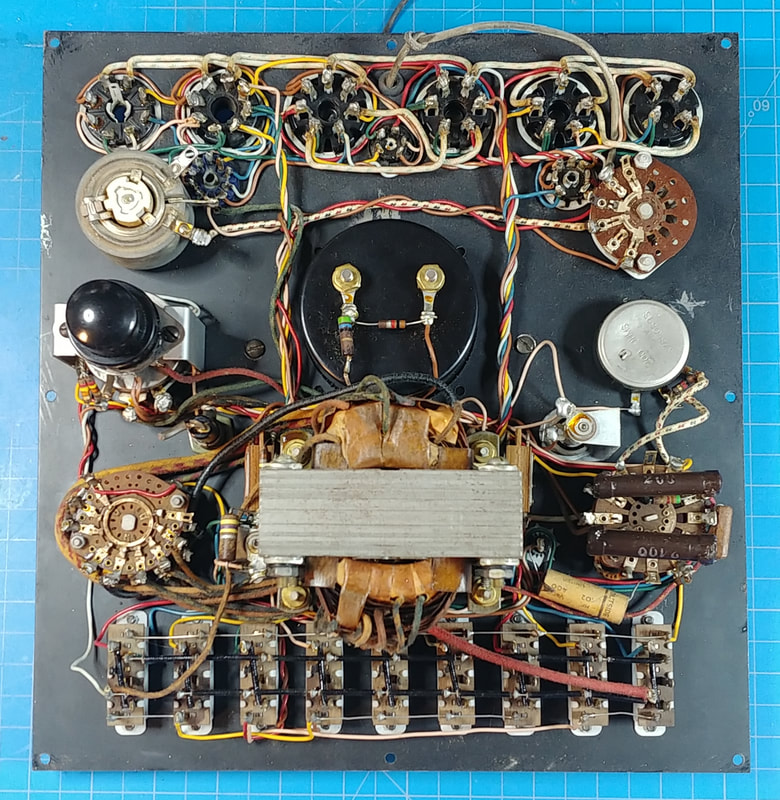

As designed this tube tester doesn't have any internal calibration adjustments. Setting the line voltage to the center scale mark of the meter is controlled by the 82K resistor on the plate of one of the 6H6 diodes, and the Gm calibration is set by the series resistor between the meter and the wiper of the 200Ω Sensitivity control.

I did find a website where someone restored a model 200 and the series resistor in that set was 110Ω, but in this set it is 56Ω. I've not seen a real schematic for a model 200 so not sure what the original resistance was, or if it was a value determined during factory calibration. |

It's also not clear what AC voltage the Line Voltage control supplied to the transformer primary when the needle was set to center scale. Using a 1% 82KΩ resistor in circuit to measure the primary voltage, I came up with 104VAC. But at 104 volts the Gm results look to be on the high side, and the filament voltages are high. For example, the 6.3 volt filament settiing is about 7VAC and the 5 volt setting is around 6 volts.

To be able to adjust the line voltage setting, I replaced the 82KΩ with a 68KΩ resistor in series with a 10KΩ potentiometer.

To set the filament voltage to 6.3VAC with a tube under test I needed to lower the voltage to the transformer primary down to 93VAC. Oddly enough this is the same voltage Hickok used in my model 550X tube tester. From what I've seen of the model 200's circuit, EMC used a design similar to the Hickok circuit.

To be able to adjust the line voltage setting, I replaced the 82KΩ with a 68KΩ resistor in series with a 10KΩ potentiometer.

To set the filament voltage to 6.3VAC with a tube under test I needed to lower the voltage to the transformer primary down to 93VAC. Oddly enough this is the same voltage Hickok used in my model 550X tube tester. From what I've seen of the model 200's circuit, EMC used a design similar to the Hickok circuit.

To calibrate the micromhos scales, I started with a 1% 56Ω resistor in series with the meter and checked several tubes that I also tested on my TV-3C and the Precise model 111. Using these numbers, plus the model 200 chart data and manufacturer's tube data, it showed the readings from the 200 were on the low side.

I replaced the 56Ω resistor with a 33Ω resistor and a 50Ω potentiometer in series, and using the test results I set the Gm calibration accordingly. This gives overall results that compare reasonably well to my other testers. There is a limit to the accuracy of a modestly priced commercial tester like this: the panel dial markings are not high precision and the Sensitivity, Bias and Line Voltage controls are a bit touchy (slight movement of a control can have a fairly significant effect on the meter reading), so high accuracy shouldn't be expected. But the results are certainly accurate enough for service use and for determining the overall condition of a tube, just not for making ultra precise Gm measurements.

I replaced the 56Ω resistor with a 33Ω resistor and a 50Ω potentiometer in series, and using the test results I set the Gm calibration accordingly. This gives overall results that compare reasonably well to my other testers. There is a limit to the accuracy of a modestly priced commercial tester like this: the panel dial markings are not high precision and the Sensitivity, Bias and Line Voltage controls are a bit touchy (slight movement of a control can have a fairly significant effect on the meter reading), so high accuracy shouldn't be expected. But the results are certainly accurate enough for service use and for determining the overall condition of a tube, just not for making ultra precise Gm measurements.

Page created 11/12/2021

Last edit 03/27/2022

Last edit 03/27/2022